FSAE Restrictor + Intake Manifold

Designing a custom Restrictor and Intake Manifold for the Duke University Motorsports 2025 NA CP2 FSAE Car.

Skills

SolidWorks

ANSYS Fluent

ANSYS Discovery

Timeline

June 2024 - Present

Team Members

Alexander Anderson

Alexandra Bergman

Defining the Problem

The Powertrain team at Duke Motorsports decided to transition from a Turbo Yamaha CP2 platform to a NA Yamaha CP2 Platform. Due to this change, I was tasked with designing a brand new rules legal and optimized restrictor and intake manifold. The team settled on a few constraints that I had to follow:

- To remain rules legal (FSAE Rule IC.1.2) and also to give Aerodynamics a rear wing bounding box, the intake must lie in the Tire Surface Envelope.

- The designed intake must be easily manufacturable in-house. It was decided that Intake Manifold parts must be able to be 3D printed on a Bambu labs P1P.

- The Intake Manifold Prototypes must have easily interchangeable runner lengths and plenum volume to allow for effective dyno testing.

Restrictor Design

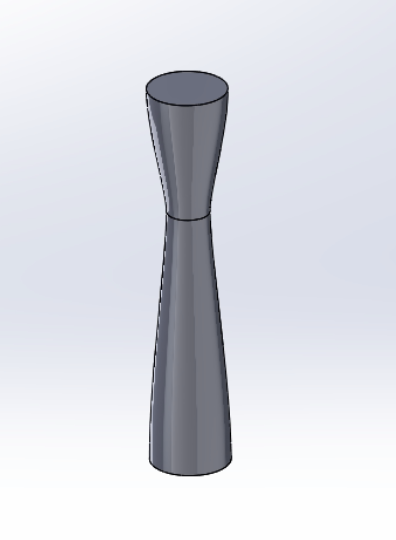

I decided to first tackle the design of the restrictor nozzle

for the manifold. In FSAE, all cars are required to have a

restrictor with a maximum diameter of 20mm if gas-fueled and

19mm if e85-fueled (FSAE Rule IC.2.4.3).

After reading a few research papers on the differences between

restrictor-nozzles, I settled on optimizing a venturi-nozzle

restrictor. I did this by running CFD simulations on

venturi-nozzle restrictors with varying converging and diverging

angles, 10-18 degrees and 6-14 degrees respectively. The goal

was to find the restrictor that optimized both pressure drop and

overall length.

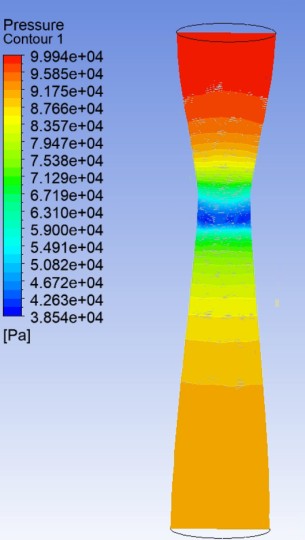

The boundary conditions for this restrictor sim was as follows:

Inlet: 101365 Pa (1 atm) Outlet: 0.074 kg/s (This number was

found by first using the NASA choked flow equation to yield

0.0703 kg/s but did not yield choked flow in simulation, so from

there I used that as a baseline and ran CFD simulations until I

was able to get an "experimental" value that yielded choke in

the restrictor.)

Final Restrictor Design + Future Steps

The next steps with restrictor design will be using the wind tunnel available on campus to experiementally verify the pressure drop and choking mass flow rate.

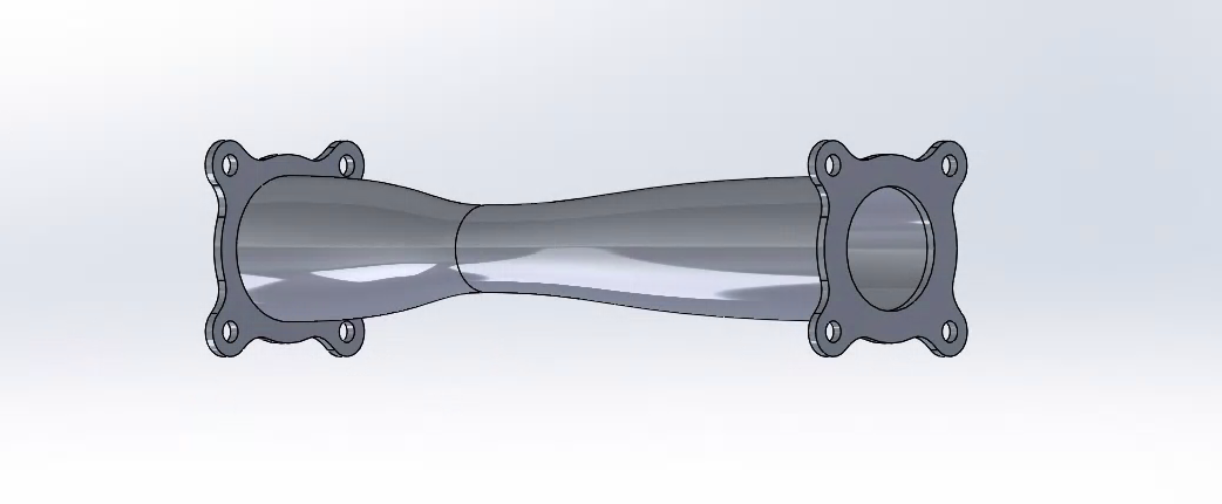

Intake Manifold Design

Next, I moved on to designing the plenum and runners. To find the ideal length of the runners, I both referenced the math from our previous intakes which used hemholtz reasonance, and my own, which used acoustic resonance. After some spreadsheet math, I determined that the ideal runner length (3RD wave tuned) is between 10.2 to 10.35 in. From there, I weighed the 3 different ways to "grab" air from the plenum and move it to the runners.

- Butt-joint esque design: This design is easy to manufacture and design, but does not efficiently retrieve fast air from the plenum.

- Tapered Runners: This design is only slightly harder to manufacture than 1, but allows for a larger radius to grab air from the plenum.

- Velocity Stacks/Bellmouths: This design is the hardest to manufacture, but is able to capture the most high speed air when compared to the other 2 designs.

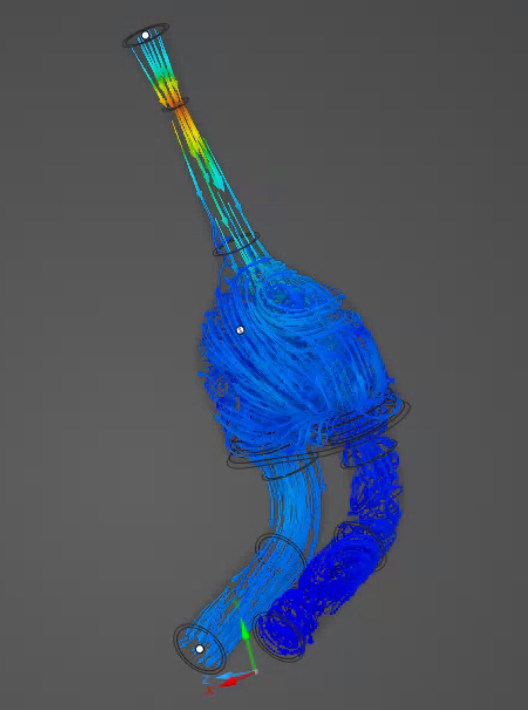

I utilized ANSYS Discovery to optimize all 3 types of plenum+runner designs (Image of CFD simulation below). I found that an optimized intake with velocity stacks outperformed the simple design significantly and the tapered one only slightly. Since the velocity stack intake manifold design is still feasible to manufacture using 3D printing, I decided to move forward with that design.

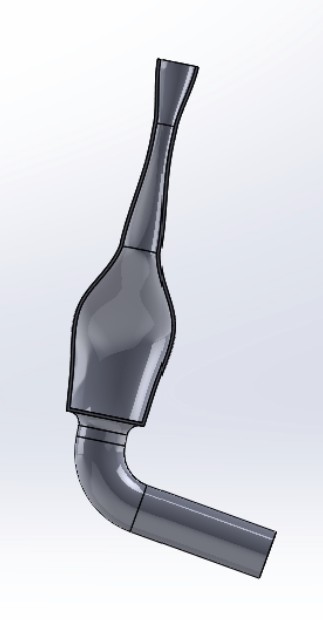

Future Steps

All of my full intake manifold CFD simulations were optimized using a steady-state approach. However, this approach does not fully recreate the actual behavior of the intake manifold. It allowed me to find deadzones and pockets in my plenum designs, but I am currently working on a transient model to simulate the airflow in the intake with the spinning of the crankshaft. I have also split my model into 3 3D printer-friendly parts (restrictor, plenum, runners). I will be 3D printing these to begin initial dyno experiemental verifications of my simulation data.

Reflection

This page encompasses most of the restrictor and intake manifold summer design I have been able to accomplish for Duke Motorsports. Coming into this project, I had zero experience with ANSYS and CFD and even how to go about designing an Intake Manifold. Thanks to the mentorship of my team leads and the many research papers available online, my knoweldge on CFD, Intake Manifolds, and overall Powertrain Design skyrocketed over the last couple months. As I go back to college, I am excited to continue the design process and finally get to see the physical model of something I have been designing and simulating all summer!